The BoatHowTo diesel course is designed to provide the information necessary to ensure you have a troublefree diesel engine installation for which you can carry out all routine maintenance. We will also set limits for amateur mechanics, describing some things you should not attempt to do and which should be left to professionals.

But before we dive into the details of installation and maintenance, we will use this lesson to talk briefly about key safety issues when working around engines, and preconditions for successful maintenance.

Commonsense safety

When working on an engine, ensure no one else can start it! Remove the ignition key or disconnect the batteries. On larger boats, especially with crew, have lock out/tagging procedures. When a boat is on the hard, if the engine is run make sure it is not put in gear, or else add protective barriers/warnings around the propeller.

There are times when we must inspect and work around operating engines.

The first thing is to ensure there is no chance someone tries to operate the engine while we are working on it!

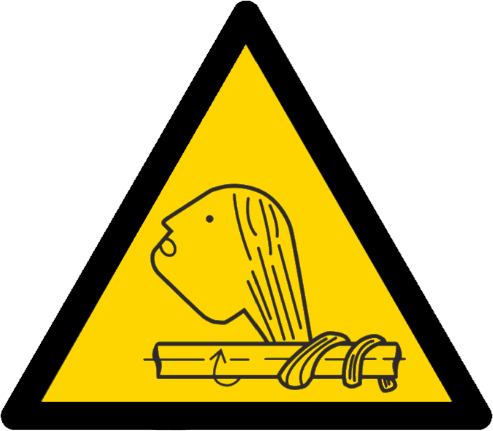

Most new engines come with protective guards around the pulleys and belts at the front of the engine. These guards are frequently removed for access and not replaced. Older engines likely never had belt guards in the first place. Given the cramped quarters in many engine compartments, it is not uncommon to be in close proximity to exposed pulleys and belts.

At the other end of the engine there is the propeller shaft coupling on all installations that have an in-line propeller. Couplings are typically in even more cramped locations and almost never have a guard over them. The coupling will have protruding bolt heads or nuts. There are times when we want access to the propeller shaft seal with the engine running and in gear. This is especially the case when adjusting the packing on a conventional stuffing box (see this lesson).

It is essential that there be no loose clothing or hair or anything else that can get caught in these belts, pulleys and couplings.

The exhaust systems on some engines can be red hot, notably if there is a turbocharger without a water-cooled jacket or heat shield, or with a damaged heat shield, or with a ‘dry’ exhaust system (in which case the exhaust pipe typically exits the engine compartment through its roof). Contact will result in instant severe burns. Even innocuous looking areas such as the oil pan can be hot enough to cause burns (the oil plays an important role in heat removal from an engine; it can rise to temperatures well above the boiling point of water).

It is important to be aware of these hazards so you can take necessary precautions.

Other than some very old engines, our engines all have a pressurized cooling system similar to what we have in our cars. The pressure on a hot engine is likely to be as high as 15 pounds per square inch (psi; 1 bar). This raises the boiling point of water and helps to make the cooling system more efficient but if the pressure cap on a header tank (it is the same as the radiator fill cap on your car) is undone when the engine is hot and the cooling system is under pressure, the water/antifreeze solution in the engine will boil explosively spewing boiling water over you and the engine. You will likely get seriously burned.

The fill cap on a header tank must never be loosened on a hot engine.

Much maintenance requires handling various fluids, notably diesel fuel, oil and antifreeze. During oil changes the oil may be hot enough to cause minor burns. There are times when we need to be wearing protective gloves and other protective clothing. This needs to be part of the maintenance equipment for the boat.

You especially need a set of quality ear protectors next to the access hatch or door to the engine compartment.

You should get in the habit of putting these on every time you open the engine compartment when the engine is running. Nigel has significant hearing loss in both ears because he worked for years around engines without always wearing ear protectors. You pay for these things twenty years later…

There are other times when engine work is physically demanding, perhaps with significant bodily contortions.

Think about your back and don’t push it to its limits.

Once damaged, backs are not easy to repair. Nigel ruptured two discs 40 years ago when in his thirties and feeling invincible. He was manhandling a failed engine out of a crane on an offshore oil production platform. He knew he should not be doing this but allowed himself to be pressured into it. He has been paying for it ever since.

It is not uncommon to be working kneeling down. Get in the habit of wearing knee protectors. Once damaged, knees can be repaired (Nigel has recently had both knee joints partially replaced) but it is not something you want to go through!

When working around batteries, always remove all metal jewelry and if possible, use insulated tools. Wear eye protection, especially when working around flooded lead-acid batteries (the type you top up with distilled water).

If you accidentally create a short circuit across the battery terminals you can do yourself a serious injury (see our electrical lessons). If your wedding ring becomes part of the conducting circuit, it can more-or-less instantly melt down to the finger bone. You should also wear eye protection, especially with flooded (wet cell) lead-acid batteries (the type you top up with distilled water).

There are additional points of electrical connection on our engines where we can accidentally put a short circuit across the cranking battery or house batteries. This is especially the case at the connection point of the cranking battery to the starter motor solenoid, and at the output stud from the alternator. If using tools in these areas (for example, when tightening the alternator's drive belt|), be sure to first turn of battery isolation switches and, if there is no switch (many cranking batteries), disconnect the battery negative conductor before starting work.

The electrolyte in all lead-acid batteries is sulfuric acid. There are times when a well-charged or overcharged battery can vent the electrolyte, occasionally forcefully. The acid will cause serious chemical burns and is especially dangerous if it gets in your eyes so take care to ensure this never happens! We address battery maintenance in detail in our Boat Electrics 101 (BE101) course.

Don't rush things!

It is all too easy when working on some engine problem, or trying to reach some hard to access component, to get distracted by the immediate project and to not pay attention to these vital safety issues. Especially for amateurs, who are not operating in a professional work environment with supervision, it is important to establish safe working practices from the beginning so that you do not become careless and take unnecessary risks.

There is no reason for anyone to get hurt around engines. It just takes more attention to commonsense safety precautions than Nigel took!

Practice: Lockout – Tagout Procedures to Prevent someone else from Starting the Engine while you’re working on the Engine. Remove the Ignition Key or Disconnect the Batteries. Ensure Operator understands not to Engage the Drive Shaft with Boat On The Hard and/or place Sign, Barrier to protect others from a Spinning Propeller.

Michael,

Excellent comments. Thank you. We will add them to the lecture notes.

Nigel

i don’t yet have a boat and therefore no engine! i am buying a 38 ft catamaran. What 30 HP engines are easiest to work on, lightest and most reliable? I have no mechanical skills at all and thus ease/simplicity is key. Sensible safety strata with having the correct and bets equipment!

Tim,

The basic maintenance is the same for all engines: oil and fuel filter changes, raw water pump impeller changes, anti-freeze replacement every couple of years, rinsing siphon valves, etc. All modern diesel engines are very reliable if installed and maintained properly.

I would say the key issue is access to the maintenance points, and how frequently the maintenance needs to be done (there is a considerable variation, for example, in recommended oil change intervals).

Then we get to a couple of other questions. An engine without a turbocharger will likely be heavier for a given power output but it is one less component to worry about (actually, typically two, because it will likely also have an intercooler). And many newer engines have electronically-controlled injection processes which adds a huge layer of electronic complexity, but with smoother running and marginally better fuel efficiency.

The electronics do not affect the basic maintenance (it remains the same) but if there are problems are likely to drive up the repair bill.

See what will fit and give you good access to the regular maintenance points!

Nigel

NB shaft drive not sail drive – less maintenance!

I just had a laugh out loud moment when Jan said:

”unless you have a really old engine”, and the manual for my 1972 (ish) Volvo Penta md2b shows up!

53 years old and still running strong! But I think it has benefitted greatly from having fresh water cooling installed from the beginning and being sailed/stored in a low-salt enviroment (gulf of bothnia).

Great course this far!

These are indeed great engines, I loved mine (also the sound if it). They and will outlive us with the right care (if they are retrofitted with a fresh water cooling system).

This is no joke – Thank you for so clearly pointing out the long-term effects of sound and physical wear and tear. I’m 55 and have been a motorcyclist since age 26. For the first year or so, I didn’t wear hearing protection and developed permanent tinnitus and hearing loss as a result. Further auditory stressors (ear plugs only mitigate so much wind damage over decades) meant hearing aids at age 52 (and they were honestly long overdue at that point,) but even with the aids it’s nothing like the real deal (and I haven’t heard silence since age 28 thanks to the tinnitus.) Tinnitus and hearing loss have been found to potentially contribute to dementia, so it’s not just about whether and what you can hear, but also about your mental well-being long-term.

I also ruptured 2 lumbar discs in my 40s through constant vibration and stress (riding long, long distances, picking bikes up, assorted normal wear and tear) and now have to be exceptionally mindful of my every movement. It’s one of the most frustrating aspects of my life.

For you younger folks out there who still have sound bodies and the ability to heal them… I know it’s almost impossible to wrap your mind around that not being the case someday, but I tell you what… it happens, it’s real, and it’s probably coming for you in time. Take care of yourselves! Preventative measures make all the difference, and not just in terms of immediate life and death, but in your overall quality of life over time.

Erin,

Thanks for sharing this.

Nigel