Engine hour meter (Source: VDO)

A pre-requisite to carrying out routine maintenance is an hour meter. It is the equivalent of an odometer in a car. Without an hour meter it is hard to keep track of when maintenance is required.

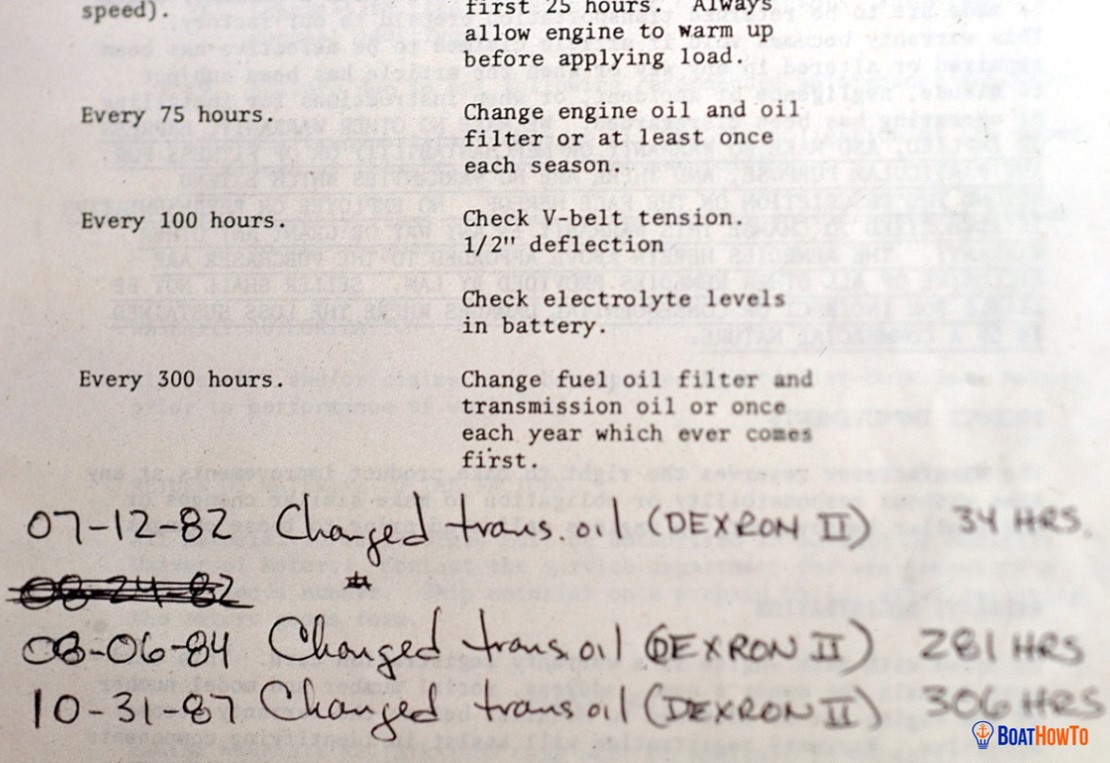

Of course, the hour meter is not a lot of use if you don’t also record when the maintenance was last done; some sort of record-keeping is a necessary adjunct. This need be no more than jotting things down in the back of an engine manual but a more systematic and likely more detailed approach is to maintain a separate, dedicated engine log.

Or you can use our BoatHowTo Engine Maintenance Planner:

In the video below, our assistant Matthias will give you a quick tutorial on how to use the planner:

Handwritten notes in the back of an old engine manual.

For those with large, expensive boats and a considerable amount of machinery there are commercial companies that will help you keep track of maintenance and spare parts. There is a significant setup fee (someone must come to the boat to log all the details necessary to get started) followed by a much lower annual fee. Aside from helping to ensure you keep up with maintenance, this creates a paper trail that has value when it comes time to sell the boat.

One such company is VesselVanguard (we provide this as an example; BoatHowTo has no commercial affiliation with this company).

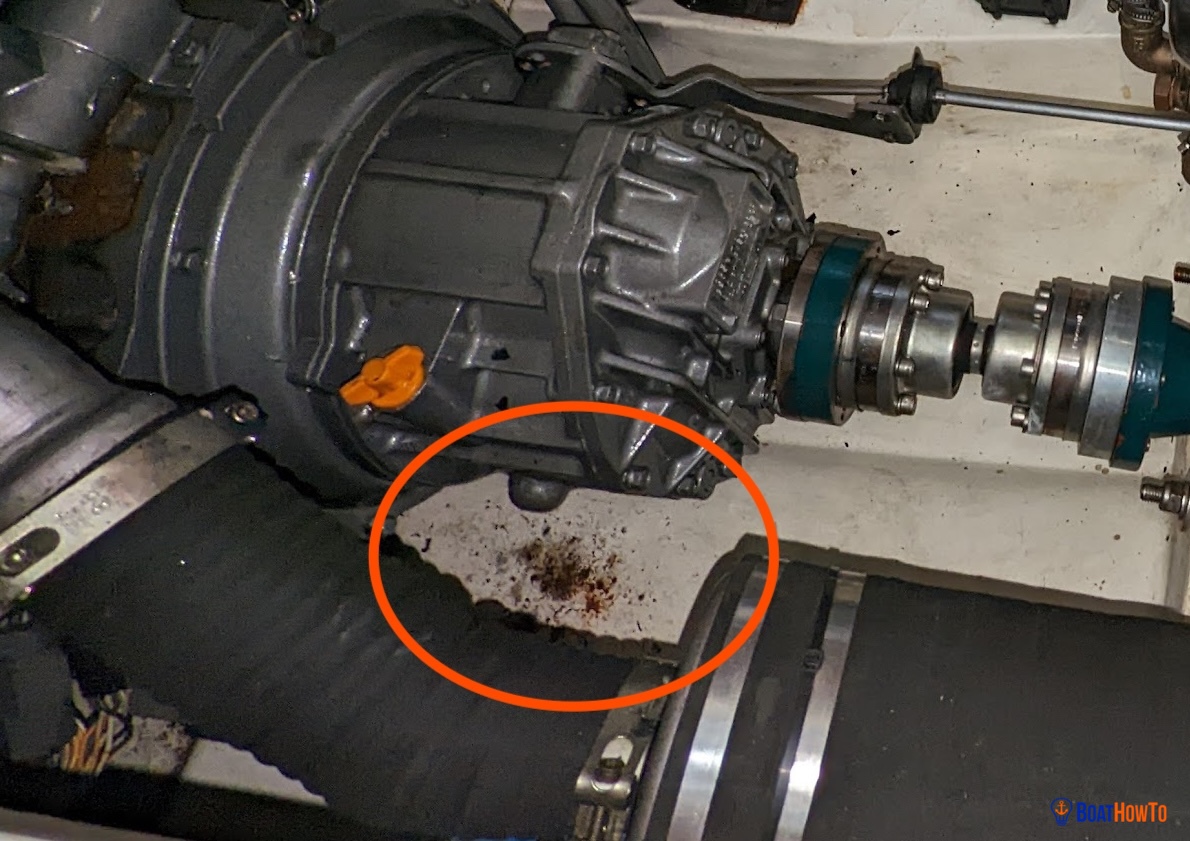

Another crucial aspect of maintenance is cleanliness. If an engine and engine compartment are kept clean, small fluid leaks, which are often a precursor of serious damage, will be immediately apparent.

If you keep your engine compartment clean, it's easier to notice problems in the making

Overhauls

The best place to work on your boat is at the dock! With this in mind, the time to take on major maintenance or other work that goes beyond routine maintenance is after a cruise and never just before one. A week into your long-anticipated cruise you do not want to find some serious unintended consequence of the work just done!

When contemplating significant overhauls, it is important to understand your own limits. Seek professional help before you get yourself into trouble and not afterwards! This is especially the case when troubleshooting. If you tear something apart and then discover you cannot find the problem, you will quite likely have destroyed the evidence that the mechanic you now hire needs in order to determine the problem. He or she may need to put things back together before starting again.

You should check the credentials of any mechanic you hire. In North America there are no licensing requirements; anyone can hang out a shingle and claim to be a marine mechanic. Word of mouth is often the best referral. Try to find a mechanic who specializes in your brand of engine (e.g., Yanmar, Volvo-Penta, Cummins, Caterpillar, John Deere…)

Spare parts should come from the engine manufacturer even though they may be twice the price of similar looking parts that fit OK. You have no way of knowing if there are critical manufacturing details that are missing from the generic part. This is especially the case when it comes to fuel and oil filters for which there are many important features which may be missing from cheaper substitute filters.

Tools

You must have the right tools for whatever work you are doing. It does not pay to buy cheap tools. With inadequate and cheap tools, at best maintenance is made more difficult, time consuming, and frustrating, and at worst you do damage, such as mangling bolt heads, which makes future work even harder. In the relevant maintenance sections, we describe various tools you may not currently have in your tool kit. Be sure to buy them before starting work! We have a bonus lesson on tools towards the end of this course.

Summary

What we have addressed in this module are commonsense safety and general maintenance procedures which are sometimes overlooked. In the following modules we will dig deeply into all routine maintenance procedures for diesel engines.

Thank you for hosting the spreadsheet. If you are able to do so, it’s really helpful to have a macro that might transfer the data from the form to a History log on a separate sheet.

This is a great idea, thanks Jason! We will look into that.

This is great! I was in the process of gathering all of this information in a (physical, paper) notebook. This is much more useful.

excellent idea with the spreadsheet, just a simple way to track the maintenance history would be great!

Thanks Björn, this is a good idea. We will look into this and see if we can create a macro that stores a backlog of the tasks.

Jan

This spreadsheet is fantastic! How do I add more items and keep the format with the additions?

Hi Katie, thanks for your comment! If you mark the full last row and copy past it to the next empty row below it should also include the functions and work just fine 🙂

What is the most efficient way to clean a dirty engine (e.g. dry paper towel, engine degreaser, soapy solution in a spray bottle)?

David,

There are specific engine degreasers sold at all automotive parts stores. Typically you spray on the degreaser and then rinse with water. Obviously, if this is an engine with a lot of electronics you need to be careful around these components!

Nigel

Thank you Nigel.

Best regards,

David

Thanks for pointing that out, Andrew! I fixed the link.